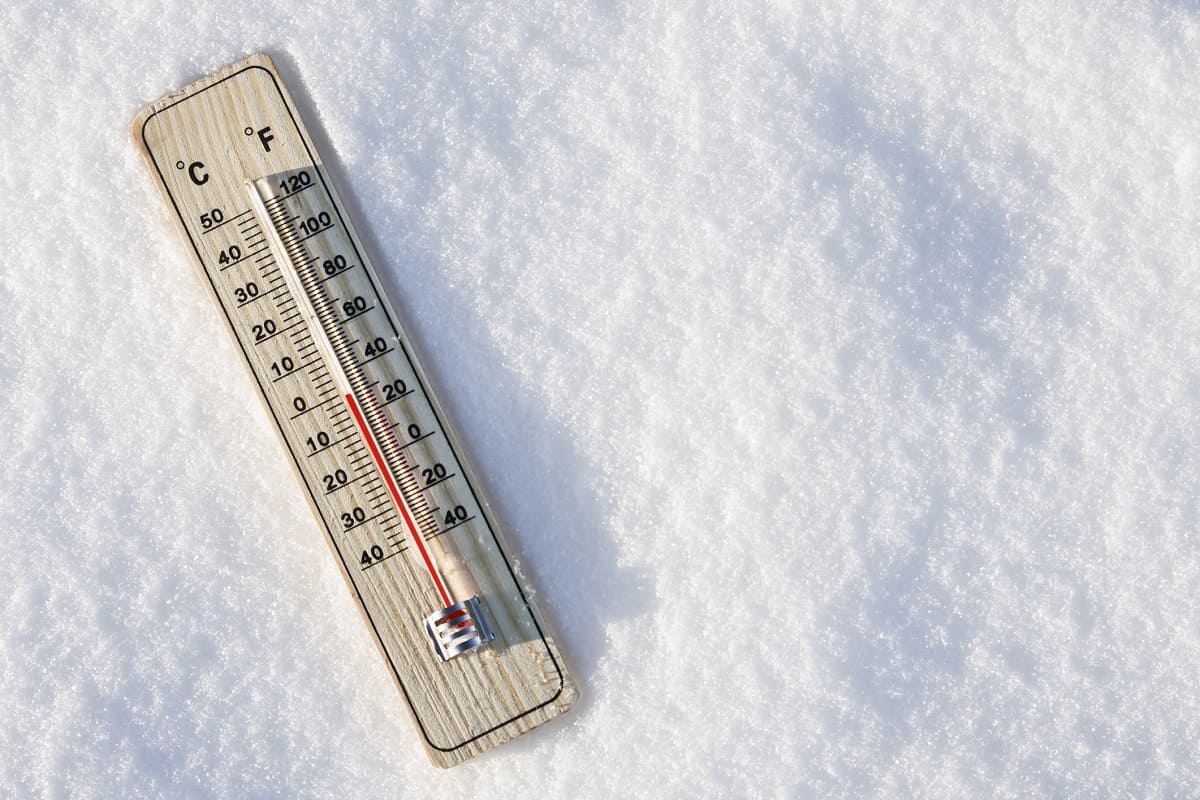

By: Kyle Russell • Weather and Climate

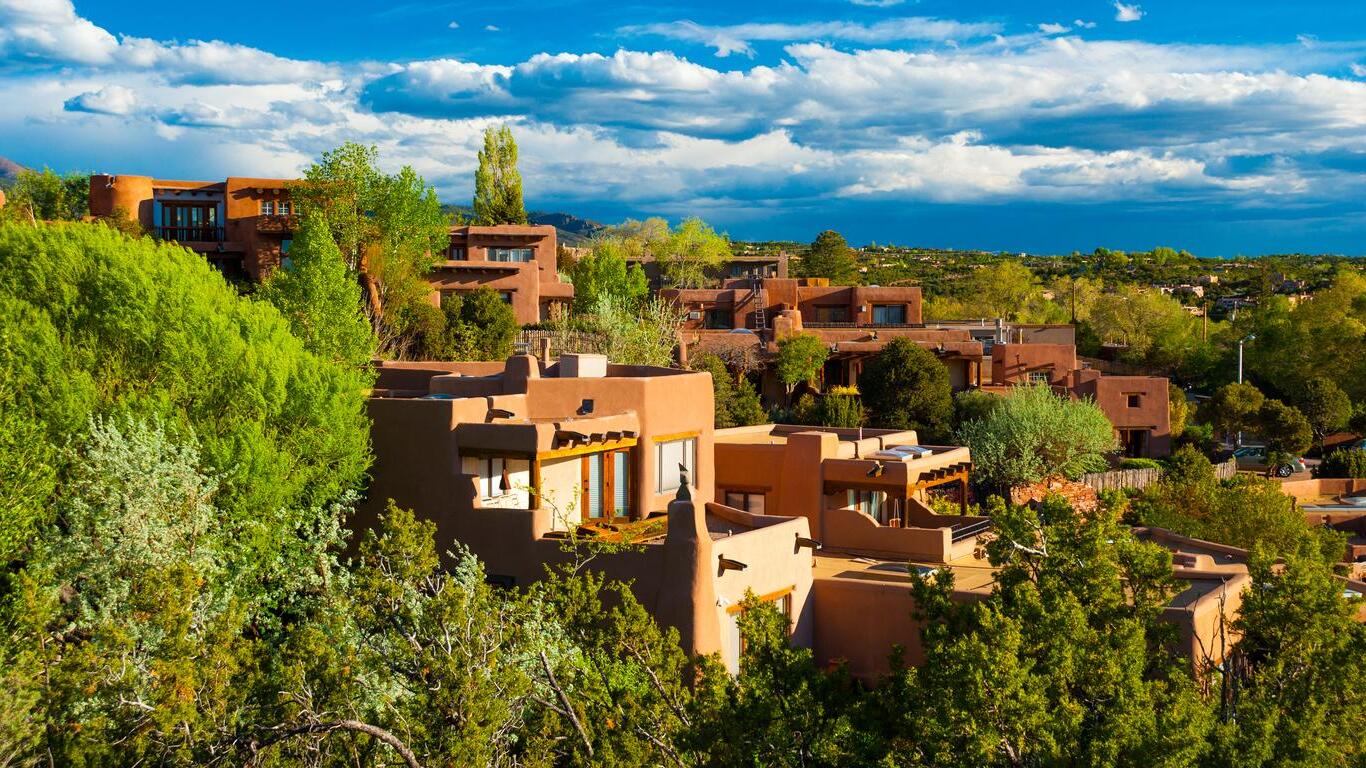

Santa Fe September Weather Guide

By: Kyle Russell • Weather and Climate

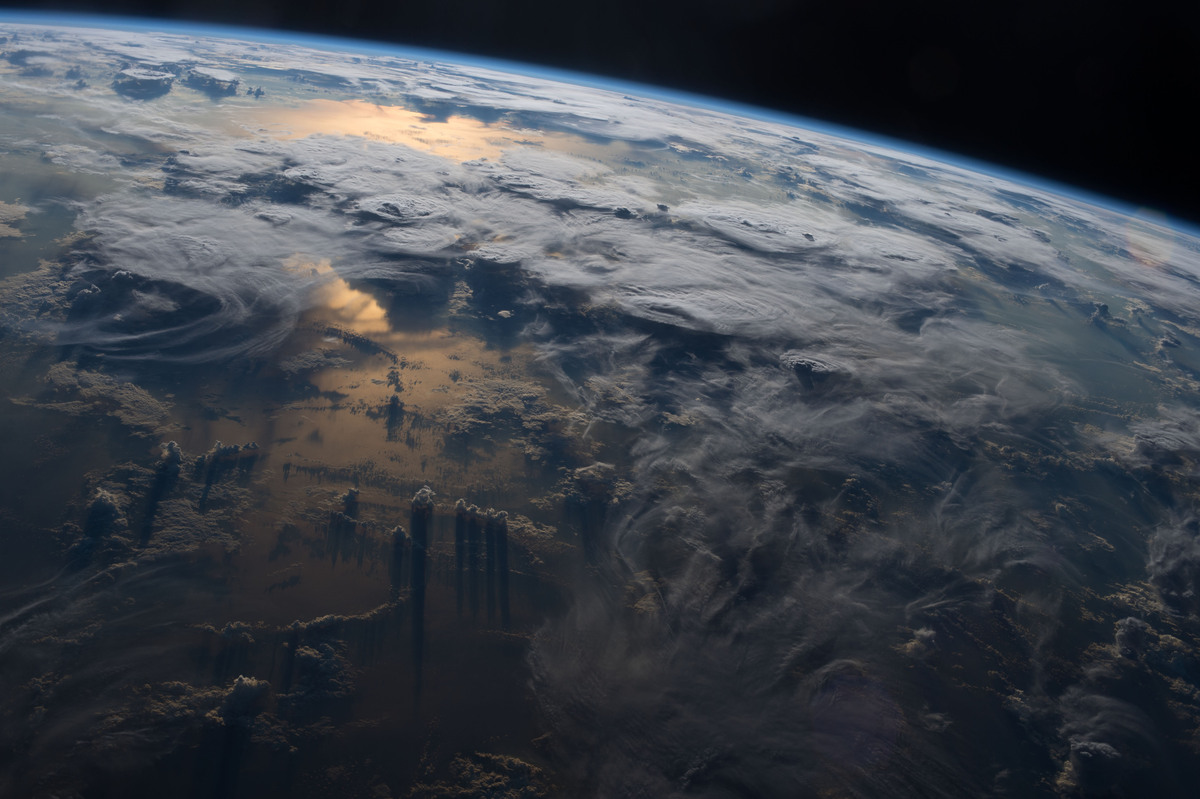

June Weather Trends Across Europe

By: Kyle Russell • Weather and Climate

Puerto Rico’s Average Temperature Guide

Inspiration & Ideas

Featured Articles

By: Kyle Russell • Culinary & Beverages

Optimal Internal Temperature For Cooking Filet Mignon

By: Kyle Russell • Culinary & Beverages

Optimal Internal Temperature For Cooking Pork

By: Kyle Russell • Science & Environment

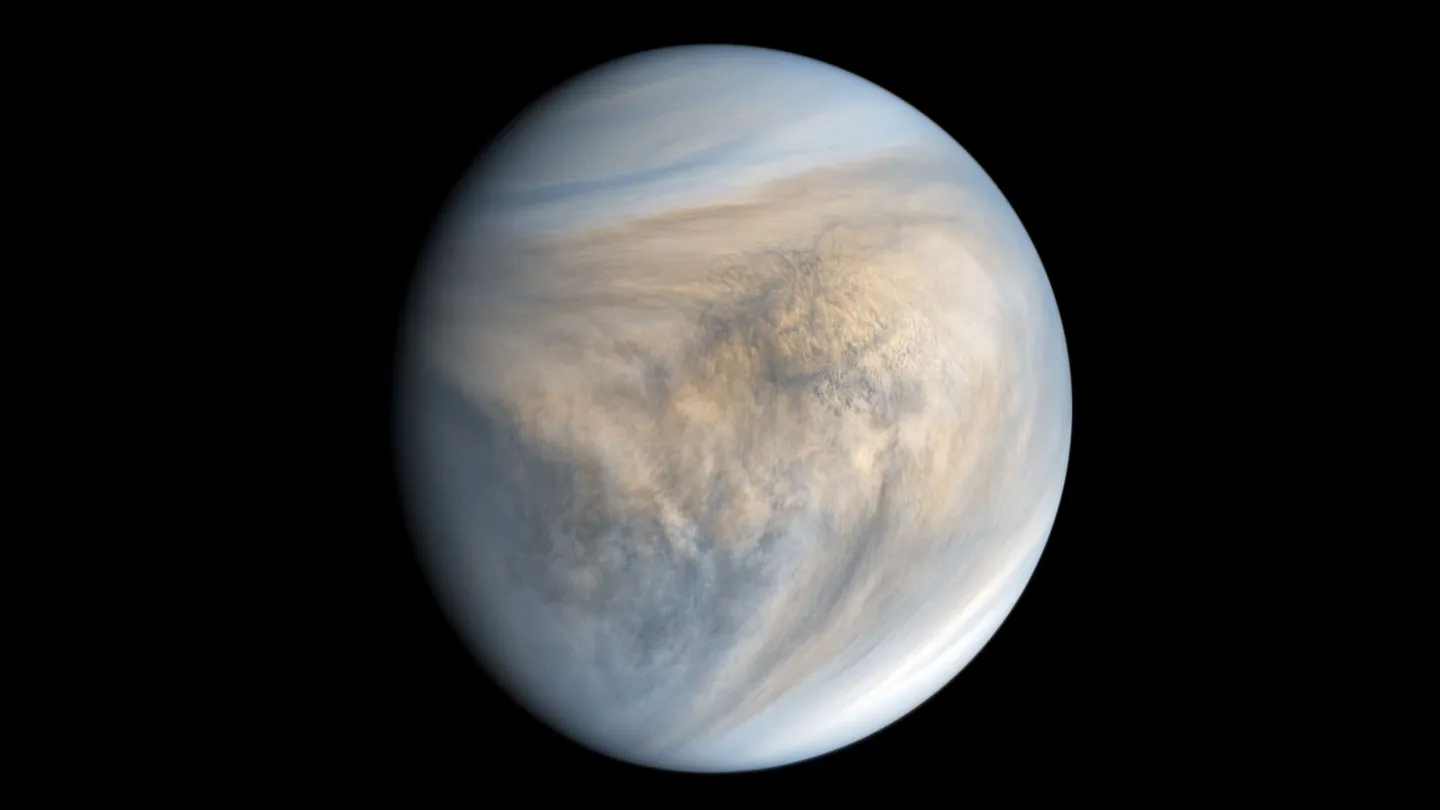

Understanding The Temperature Of Venus

By: Kyle Russell • Science & Environment